Yog tias koj xav ua ib lub hauv pem teb zoo uas tsis yooj yim hnav (lossis lub hauv pem teb zoo uas kho tau zoo), koj yuav tsum xav txog lub zog ntawm lub hauv paus pob zeb, tshwj xeeb tshaj yog qhov tiaj tiaj. Lub hauv pem teb zoo uas tsis yooj yim hnav tsis yog tsuas yog muaj feem cuam tshuam nrog qhov zoo ntawm cov pob zeb uas tsis yooj yim hnav xwb. Yuav tsum muaj cov hauv paus zoo dua. Daim ntawv no lub hom phiaj yog muab rau koj cov cuab yeej siv laser leveling thiab cov thev naus laus zis hauv pem teb uas tsis yooj yim hnav thiab ua tiav tshaj plaws. Cov ntsiab lus hauv qab no yog cov txheej txheem tsim kho uas Shanghai Jiezhou Engineering & Mechanism Co., Ltd. tau sau tseg raws li ntau xyoo ntawm kev paub hauv kev lag luam. Rau koj siv.

Cov txheej txheem kev tsim kho: kev kho cov hauv paus → kev teeb tsa lub tsev rau khoom → kev pub pob zeb → tshuab laser leveling paving, vibrating thiab compacting → kis cov hlau sib sau ua ke → calendering thiab slurry extraction → polishing → watering thiab curing → kev sib koom ua ke thiab grouting.

Daim duab siv laser screed

Kev kho mob hauv paus

1. Ua ntej, cov khib nyiab ntawm txoj kev hauv paus yuav tsum raug tshem tawm thiab yuav tsum tsis muaj lwm yam khoom seem ntawm qhov chaw ntawm txoj kev hauv paus.

2. Siv rab txheeg los txiav qhov chaw uas tawm los ntawm qhov chaw kom qhov siab ntawm qhov chaw sib npaug. Xyuas seb qhov tiaj tiaj ntawm txoj kev hauv paus puas ua tau raws li tus qauv hauv ± 2cm ntawm qhov siab tsim kom paub tseeb tias qhov tuab ntawm cov pob zeb ua vaj tse.

Cov chaw teeb tsa qauv

Ua ntej, raws li qhov chaw ntawm cov hlau ntawm tag nrho cov nroj tsuag, cov qauv tsim, kev npaj formwork, kev coj mus los ntawm lub tsheb thiab cov yam ntxwv ntawm kev tsim kho ntawm cov khoom siv leveling, ib txoj kev tsim kho txhim khu kev qha tau tsim. Cov formwork ruaj khov yuav tsum tau teeb tsa hauv thaj chaw tsim kho. Cov formwork yuav tsum yog cov formwork tshwj xeeb ua los ntawm cov hlau channel, thiab qhov qhib sab saud ntawm cov formwork yuav tsum tau kho kom nws tiaj tus thiab sib xws sab hauv thiab sab nraud.

Teem txheej swb

Tom qab ua tiav daim formwork lawm, thaj chaw tsim kho yuav tsum tau npog nrog zaj duab xis yas kom cais cov hauv paus ntawm cov pob zeb ua ke kom ua ib txheej swb.

Kev sib txuas lus reinforcement mesh

1. Lub mesh txhawb nqa yuav tsum tau ua tiav los ntawm kev sib koom ua ke thiab sib koom ua ke hauv qhov chaw, thiab thauj mus rau qhov chaw teem tseg rau kev teeb tsa tom qab khi. Qhov chaw txhawb nqa yuav tsum huv si, tsis muaj av qias neeg, xeb, thiab lwm yam kom ntseeg tau tias cov khoom siv raw zoo. Lub mesh txhawb nqa yuav tsum khi tag nrho, thiab qhov sib nrug thiab qhov loj me yuav tsum ua tau raws li qhov tsim thiab cov kev cai tshwj xeeb. Tom qab khi, xyuas lub mesh txhawb nqa kom pom tias cov txheej tiv thaiv puas txaus, seb qhov khi puas ruaj khov thiab seb puas muaj qhov xoob.

2. Ua ntej nchuav cov pob zeb ua vaj tse, cov neeg ua haujlwm yuav tsum teeb tsa nws rau ntawm qhov chaw uas tau teem tseg. Qhov loj ntawm cov ntaub thaiv pob zeb yog 3M × 3m.

Kev siv lub tshuab laser leveling

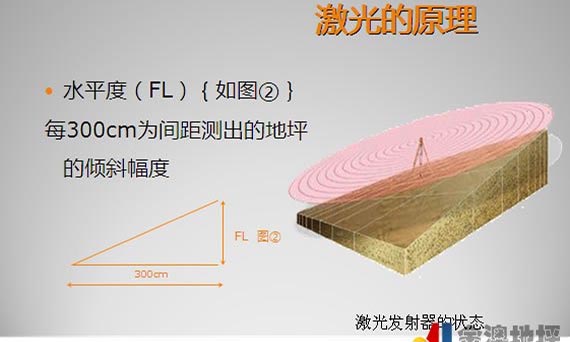

Ua ntej nchuav cov pob zeb ua vaj tse, lub tshuab laser leveling yuav tsum tau debugged. Tsa thiab theem lub laser transmitter, thiab kho qhov siab thiab qib ntawm lub taub hau leveling ntawm lub tshuab leveling pob zeb raws li lub teeb liab xa mus kom nws sib xws nrog qhov siab ntawm cov av pob zeb. Tib lub sijhawm, kho qhov siab sib txawv ntawm ob qho kawg ntawm lub taub hau leveling hauv 0.5 hli. Ua ntej kev tsim kho loj, siv cov khoom siv rau kev sim ntau lawm thiab xyuas kom meej tias tsis muaj qhov yuam kev.

Kev nchuav pob zeb ua vaj tse

1. Yuav tsum siv cov pob zeb ua lag luam. Kev ua haujlwm ntawm cov pob zeb ua lag luam yuav tsum ua tau raws li qhov yuav tsum tau ua ntawm cov lus qhia tshwj xeeb, thiab qhov poob ntawm cov pob zeb rau hauv daim ntawv yuav tsum tswj tau ntawm 160-180 hli.

2. Cov pob zeb yuav tsum tau muab tso rau ntawm qhov kawg kom zoo. Thaum cov pob zeb sib xyaw raug nchuav rau hauv daim ntawv formwork, kev thauj khoom yuav tsum tau sib xyaw thiab qeeb, thiab qhov tuab virtual yuav tsum siab dua li 2cm ntawm daim ntawv formwork. Yog tias tsim nyog, cov khoom siv yuav tsum raug txo lossis ntxiv, thiab cov ntu ntsug thiab kab rov tav yuav tsum ua tau raws li qhov yuav tsum tau ua. Cov pob zeb yuav tsum tau muab tso rau ntawm qhov txuas ntxiv yam tsis muaj kev cuam tshuam.

3. Tom qab nchuav cov pob zeb ua vaj tse lawm, cov pob zeb ua vaj tse yuav tsum tau muab sib npaug zos manually hauv qhov ntau ntawm lub caj npab telescopic ntawm lub tshuab leveling, thiab tom qab ntawd kev co, kev sib zog thiab kev sib npaug yuav tsum ua tiav ib zaug nrog lub tshuab laser leveling. Hauv cov txheej txheem leveling, siv ib qho kev taw qhia ua lub hauv paus ntsiab lus, thiab tso rov qab los ntawm sab hauv mus rau sab nraud ib kauj ruam zuj zus.

4. Cov cheeb tsam uas tsis tuaj yeem ua kev tsim kho tshuab, xws li cov ces kaum thiab cov ncej hlau, yuav tsum tau nias thiab teeb tsa tes.

Kev tsim kho pem teb uas tiv taus kev hnav

Ua ntej pib teeb tsa cov pob zeb ua vaj tse, yuav tsum siv lub disc trowel los txhuam kom txog thaum cov slurry tawm, thiab cov hardener yuav tsum tau faib sib npaug zos rau ntawm qhov chaw ntawm cov pob zeb ua vaj tse. Tom qab cov hardener nqus tau ib qho dej ntau, pib sib tsoo; Tom qab sib tsoo ntxhib, txheej thib ob ntawm hardener yuav tsum tau nthuav tawm, thiab qhov ntau ntawm cov khoom yuav tsum yog 1/3 ntawm cov txheej txheem dhau los. Kev sib tsoo hla yuav tsum tau ua thaum sib tsoo, thiab tsis pub sib tsoo ploj.

Kev sib tsoo thiab polishing ntawm cov hlau trowel

1. Tom qab siv laser leveling, cov pob zeb yuav tsum tau tsa thiab ua kom tiav nrog lub trowel ua ntej thiab tom qab teeb tsa thawj zaug. Kev siv disc grinder los txhuam cov pob zeb yuav tsum tau ua ntau zaus raws li qhov tawv ntawm cov txheej saum npoo. Kev ua haujlwm ntawm kev txhuam cov pob zeb yuav tsum tau kho kom haum raws li qhov tawv ntawm cov av pob zeb, thiab kev siv tshuab txhuam cov pob zeb yuav tsum tau ua ntsug thiab kab rov tav.

2. Ua ntej teeb tsa zaum kawg, hloov lub disc ntawm lub grinder ua ib rab riam, thiab kho lub kaum sab xis rau kev sib tsoo thiab polishing. Feem ntau, kev ua haujlwm polishing yog ntau dua 2 zaug kom ua rau hauv pem teb ci ntsa iab.

Qhov txiav:Cov pob qij txha yuav tsum tau txiav raws sijhawm 2-3D tom qab kev tsim kho ntawm qhov chaw uas tsis yooj yim hnav. Yuav tsum txiav ntub rau kev txiav cov pob qij txha, nrog rau qhov tuab ntawm 5cm thiab qhov tob tsis pub tsawg dua 1/3 ntawm qhov tuab ntawm cov pob zeb. Cov xov txiav yuav tsum ncaj thiab zoo nkauj.

Kho: Tom qab ua tiav cov pob zeb tiav lawm, yuav tsum muab zaj duab xis npog thiab muab dej rau kom nws khov. Thaum lub sijhawm khov, thaum lub zog ntawm cov pob zeb tsis txog 1.2MPa, tsis pub leej twg taug kev saum nws.

Kev siv caulking

1. Tom qab hauv pem teb qhuav tau ob lub lis piam lawm, ntxuav qhov sib koom ua ke kom huv si thiab tshem tawm tag nrho cov khoom me me thiab cov hmoov av ntawm qhov sib koom ua ke.

2. Yuav tsum siv cov tshuaj polyurethane sealant uas muaj zog ntev thiab khov sai los txhaws qhov sib txuas uas ntsws.

Kev tswj hwm kev ntsuas

1. Cov ntaub ntawv siv rau ntawm qhov chaw yuav tsum tau txais kev pom zoo los ntawm qhov chaw, thiab yuav tsum tau muab tso rau ntawm qhov chaw uas tau teev tseg tom qab dhau qhov kev pom zoo. Nco ntsoov tias cov ntaub ntawv uas muaj cov cai tiv thaiv dej yuav tsum ua raws li cov kev ntsuas tiv thaiv dej noo thiab nag.

2. Muab cov neeg ua haujlwm tswj kev tsim kho uas muaj kev paub dhau los thiab cov neeg ua haujlwm tsim kho uas muaj kev txawj ntse. Ua ntej kev tsim kho, cov neeg ua haujlwm tsim nyog yuav tsum tau teeb tsa los qhia txog kev siv cov tshuab thiab cov cuab yeej tsim kho kom raug thiab kev tswj cov txheej txheem tseem ceeb, kom ntseeg tau tias cov neeg ua haujlwm tsim kho muaj kev txawj ntse hauv kev ua haujlwm ntawm txhua txoj kev.

3. Cov tshuab thiab cov cuab yeej siv hauv kev tsim kho yuav tsum ua tau raws li qhov yuav tsum tau ua, nyob rau hauv qhov zoo, thiab npaj qee cov cuab yeej tseem ceeb.

4. Qhov chaw tsim kho yuav tsum huv si thiab huv si kom tiv thaiv cov hmoov av thiab lwm yam khoom tsis pub ua rau hauv av qias neeg.

5. Cov hnab, cov khib nyiab thiab lwm yam khoom pov tseg uas tso rau ntawm qhov chaw yuav tsum tau muab tshem tawm txhua hnub kom ntseeg tau tias qhov chaw raug tshem tawm tom qab ua haujlwm. Yog tias muaj cov khoom pov tseg tshwj xeeb, txoj kev kho yuav tsum ua raws li cov kev cai rau kev kho cov khoom tshwj xeeb.

Thaum kawg, ntxiv rau kev ua raws li cov txheej txheem saum toj no, lub hauv pem teb zoo uas tiv taus kev hnav kuj xav tau kev sib koom tes thiab kev koom tes ntawm cov pob zeb thiab lub hauv pem teb uas tiv taus kev hnav.

Tsim muaj xyoo 1983, Shanghai Jiezhou Engineering & Mechanism Co., Ltd. tsom mus rau R & D, kev tsim khoom thiab kev muag khoom ntawm cov tshuab hauv thaj chaw ntawm cov pob zeb hauv pem teb. Lub tshuab Laser screed, lub zog trowel, lub tshuab txiav, lub phaj compactor, tamping rammer thiab lwm yam tshuab siv cov thev naus laus zis tshiab thiab tau txais kev qhuas los ntawm cov neeg siv khoom.

Nws muaj cov neeg siv khoom hauv ntau tshaj 100 lub tebchaws thoob ntiaj teb thiab yog tus thawj coj hauv kev lag luam. Yog tias koj muaj lus nug, koj tuaj yeem hu rau DYNAMIC, thiab peb yuav pab koj tag nrho lub siab!

Lub sijhawm tshaj tawm: Lub Yim Hli-24-2022